The Buzz on Digital Printing

Table of ContentsWhat Does Digital Printing Do?The smart Trick of Digital Printing That Nobody is DiscussingA Biased View of Digital Printing

Digital printing likewise needs minimal setup. Below are the vital ways in which electronic printing supports greener methods: One of the considerable ecological benefits of digital printing is lowering waste (Digital Printing). Typical printing approaches, like lithographic printing, frequently waste considerable amounts of paper and ink throughout the configuration stage.

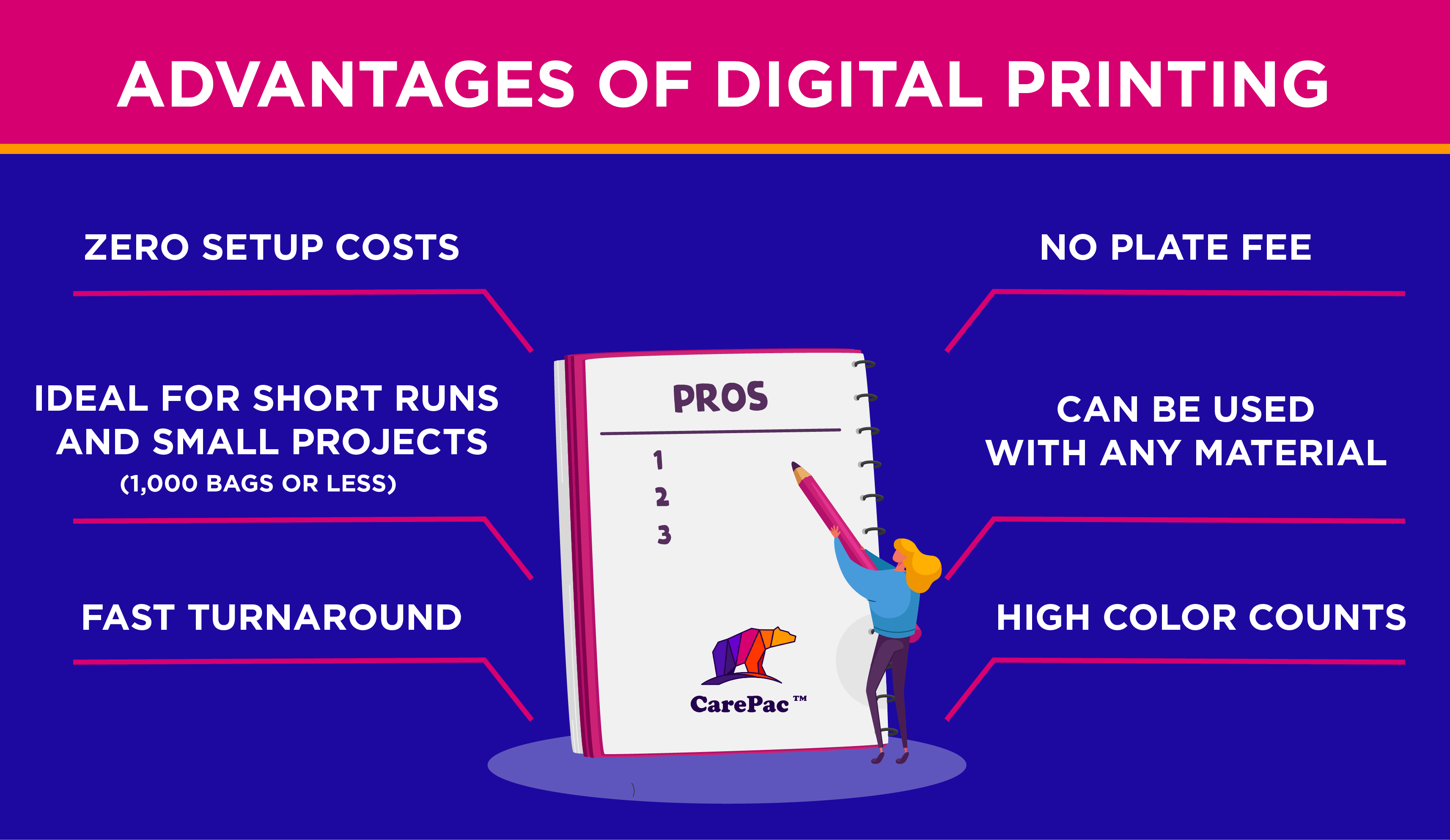

Digital printing machine remove the you can try this out requirement for these plates, significantly decreasing arrangement prices. Digital printing presses can include variable information into your prints, which enables extremely tailored marketing materials (Digital Printing). By personalizing your advertising and marketing materials, you can raise engagement with prospective consumers and enhance the opportunities of converting them into real clients

Digital printing machine supply excellent shade consistency and accuracy, resulting in better prints. With electronic printing, you can be sure that the shade of your prints will correspond from one print job to the next. Several years ago, lots of consumers did decline direct-injection digital printing because the high price. The purchase price of a set digital printing devices is at the very least 150%of the conventional printing and coloring tools, which increases the.

The Basic Principles Of Digital Printing

In order to stop rust of the nozzle, the ink for digital printing is much more pricey than the ink for typical printing, and extra ink purification is necessary throughout the printing procedure. In electronic inkjet printing, the pattern is directly published on the textile, removing the plate making in rotary screen printing. Yes, are a lot more costly than standard printing inks, but the electronic printing procedure can save ink consumption.

Today, the electronic direct-injection printing maker has gone from proofing to the stage of medium-sized and large-sized production. Both printing homes and brand name proprietors are mindful of the development potential of digital printing, and are willing to increase investment in digital printing. Digital printing is extra cost-effective for short print runs since it requires less pre-press activities and less configuration than countered printing.

Variable information printing, such as straight mail with customized codes and addresses, is ideally fit for electronic printing. Digital quick printing just needs four actions of layout, evaluation, printing and binding to obtain everything done. Digital fast printing has an unmatched advantage: print on need.